Rapid wound healing system

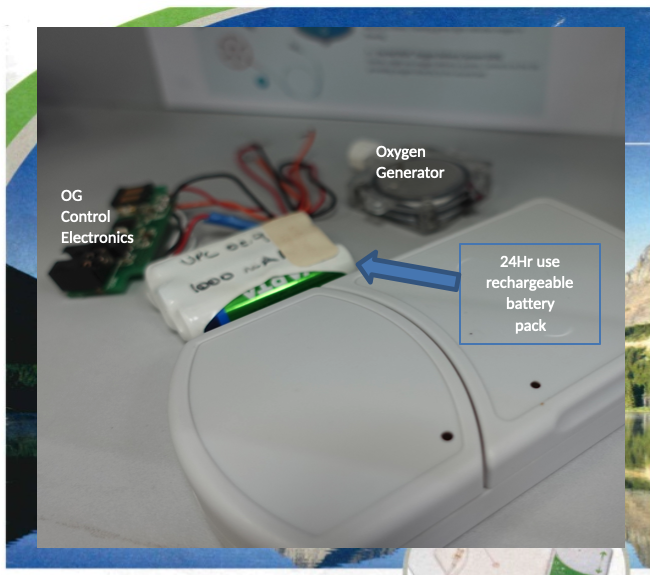

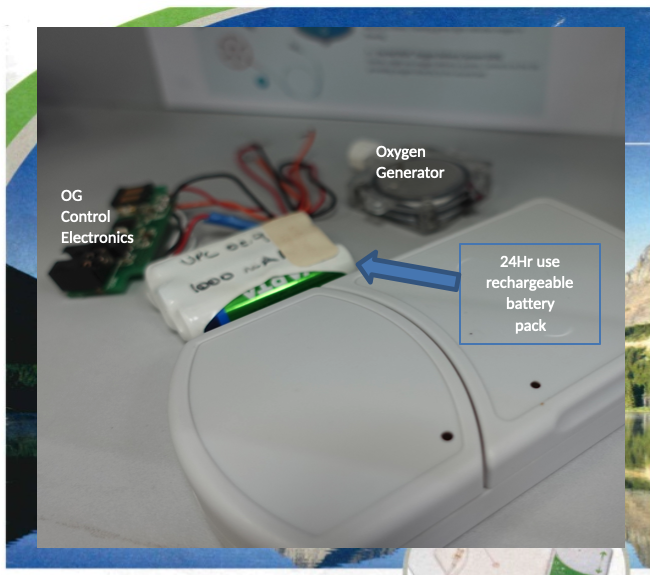

This roundpeg led phase 2 project required an innovative design approach to take a large disposable battery prototype to a small rechargeable ambulatory system ready for approval and market launch.

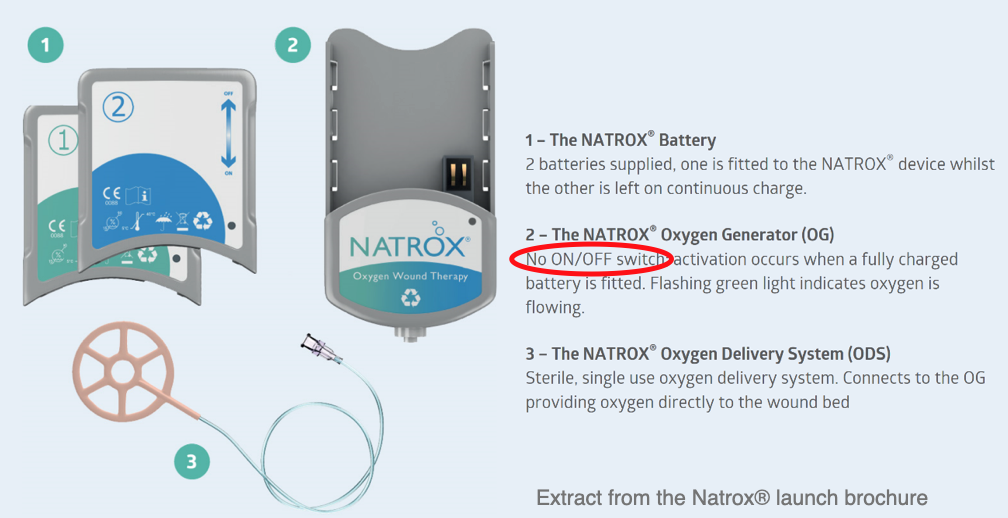

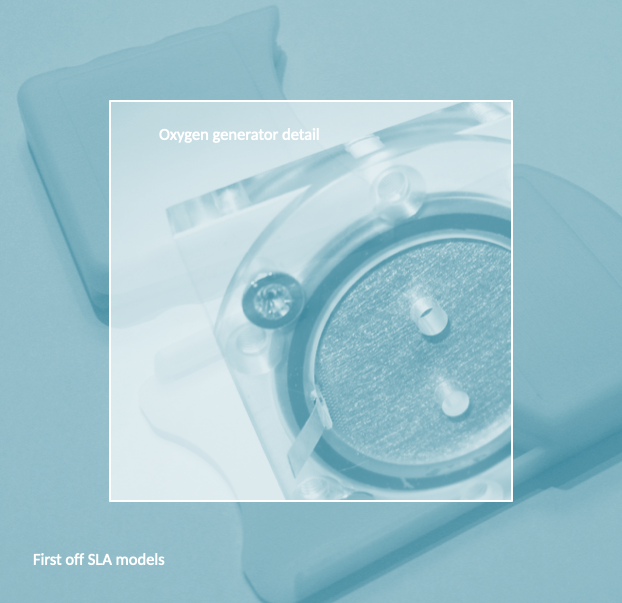

The Natrox® system uses electrical energy to generate oxygen from water in the air. The smart oxygen generator came out of Cambridge University, that was put into engineering practice by roundpeg in phase 1.

Human factors needed to be simple, intuitive and fool-proof for all users, whether in a hospital setting or at home. The ‘no-power switch’ principle was agreed; plug in a battery and a flashing green LED starts – oxygen is now being delivered to heal the wounds.

Rapid wound healing system

This roundpeg led phase 2 project required an innovative design approach to take a large disposable battery prototype to a small rechargeable ambulatory system ready for approval and market launch.

The Natrox® system uses electrical energy to generate oxygen from water in the air. The smart oxygen generator came out of Cambridge University, that was put into engineering practice by roundpeg in phase 1.

Human factors needed to be simple, intuitive and fool-proof for all users, whether in a hospital setting or at home. The ‘no-power switch’ principle was agreed; plug in a battery and a flashing green LED starts – oxygen is now being delivered to heal the wounds.

No on/off switch saved weight and complexity, improving reliability.

Adding voltage and current monitoring to a low-power long-life rechargeable battery system is not trivial. You must take care or your monitoring methods reduce performance.

The Natrox® target was 24 hour oxygen generation from a single, throughout the 500 life-time pack charge cycles.

It is challenging to test multiple battery packs when the target time is not being met. UPC worked long days and started early in the morning to identify root cause of ‘lost’ battery life.

CTQ target met – root causes identified and fixed.

Systematically UPC went through every element to see if they were performing as their unit specification stated. Under time pressure close to product launch, this is challenging.

The RCA into lost battery life found the elements:

- Long-term behaviour of the oxygen generator

- High-resistance custom connectors

- Heating effects from connector resistance

Fixing these relatively minor issues quickly returned battery life to above the 100% target.

We learnt to monitor everything you can afford to, at the outset of design verification programmes.

UPC always learning, refining methods, enabling excellence.