Green propellant leakage and moisture ingress

The world is facing unparalleled issues with Global Warming, now re-branded as Climate Change started in the industrial age by emissions of carbon dioxide into the atmosphere. The CO2 in the upper atmosphere blankets the earth, letting in solar energy, but trapping the infrared energy as heat.

Recipharm make inhaler metering valves for drug companies who fill cans with drug formulations, seal them with the valve by crimping and then gas them with HFA. The HFA is what generates the aerosol spray when the inhaler is fired.

134a is the most common inhaler gas and has a global warming potential (GWP) of around 1500. This means that for every gramme of 134a used, it is equivalent to 1.5 kg of CO2 in the upper atmosphere.

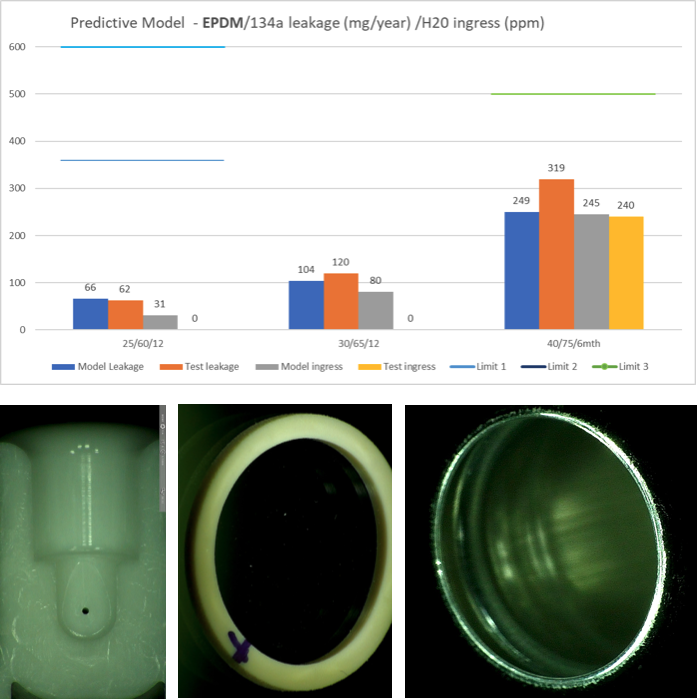

In 2019 UPC first modelled the diffusion leakage from existing 134a inhalers with Recipharm valves at varying temperatures and relative humidity, verifying the model with data from customers. The accuracy was reasonable, so the first stage gate was passed.

Green propellant leakage and moisture ingress

The world is facing unparalleled issues with Global Warming, now re-branded as Climate Change started in the industrial age by emissions of carbon dioxide into the atmosphere. The CO2 in the upper atmosphere blankets the earth, letting in solar energy, but trapping the infrared energy as heat.

Recipharm make inhaler metering valves for drug companies who fill cans with drug formulations, seal them with the valve by crimping and then gas them with HFA. The HFA is what generates the aerosol spray when the inhaler is fired.

134a is the most common inhaler gas and has a global warming potential (GWP) of around 1500. This means that for every gramme of 134a used, it is equivalent to 1.5 kg of CO2 in the upper atmosphere.

In 2019 UPC first modelled the diffusion leakage from existing 134a inhalers with Recipharm valves at varying temperatures and relative humidity, verifying the model with data from customers. The accuracy was reasonable, so the first stage gate was passed.

Prediction with Verification, enhanced digital inspection, and micron metrology all combine to provide inhaler integrity

In a pressurised Metered Dose Inhaler (pMDI) the filled canister, with the valve fixed on top, forms the primary drug container (PDC). Integrity of this drug container throughout life was the aim for UPC’s predictions around the diffusion of gases in and the new green propellants out of the inhaler canister.

By combining four scaling factors affecting the diffusion of gases – from the Law’s of Physics, UPC was able to quickly rate different gasket material types for leak and ingress rate.

A further model refinement was made using empirical data and material polarity to produce an observed algorithm, and so a fifth scaling factor. Not first principles, but a practical approach to solving a real-world problem with a deadline in sight.